Flexible adhesives play a crucial role in modern manufacturing and assembly processes, offering high resiliency, excellent adhesion, and tensile strength while accommodating movement and flexibility. These adhesives are available in a range of formulas such as elastomeric adhesives, MS polymer adhesives, and flexible cyanoacrylate adhesives, each tailored to meet specific bonding needs where elasticity and pliability are essential.

Key Benefits of Flexible Adhesives

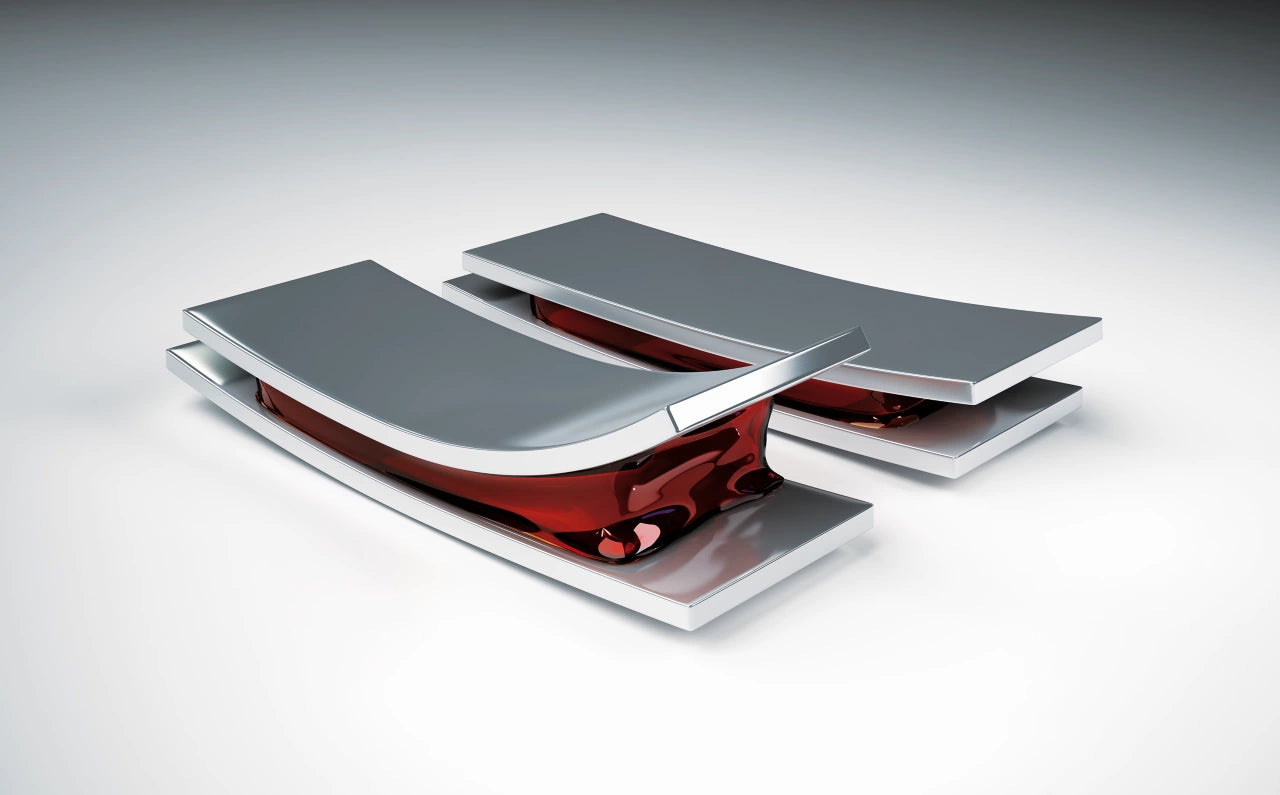

One of the primary advantages of flexible adhesives is their versatility. They can bond a wide variety of substrates, from metals and plastics to composites, making them ideal for industries requiring non-mechanical bonding of moving parts and components. Whether used in gap-filling applications or sealing techniques, flexible adhesives ensure strong, reliable adhesion while providing resistance to environmental factors such as UV rays and weathering. This makes them suitable for outdoor applications like vehicle panels, exterior building structures, and signage, where materials experience varying degrees of thermal expansion.

The adaptability of flexible adhesives also makes them particularly useful for materials with different coefficients of thermal expansion. As temperatures fluctuate, the adhesives stretch and contract with the bonded materials, ensuring the joint remains intact without placing undue stress on the structure. This is particularly important in applications where large surfaces, like panels or outdoor structures, are subject to different thermal exposures throughout the day.

Applications Across Multiple Industries

Flexible adhesives are used in almost every industry, from automotive and aerospace to electronics and construction. Their ability to create sag-resistant joints with aesthetically pleasing finishes makes them a popular choice in design-sensitive applications. In automated production environments, liquid flexible adhesives can be robotically dispensed to enhance efficiency. This streamlines the bonding process while reducing waste and labor costs.

Choosing the right flexible adhesive requires understanding the substrate, its intended use, and environmental factors. Henkel’s TEROSON® and LOCTITE® brands offer a comprehensive range of flexible adhesives tailored to various applications. With high-performance attributes such as UV and weather resistance, broad-spectrum adhesion, and integration with automated systems, these adhesives help manufacturers maintain quality and reduce costs.

Conclusion

In today’s industries, where materials, movements, and environments vary significantly, flexible adhesives provide a reliable solution for bonding applications. Their combination of strength, elasticity, and versatility ensures high-performance joints that stand the test of time, making them an indispensable tool for modern manufacturing. Whether it’s automotive parts, building materials, or electronics, flexible adhesives can be adapted to meet the challenges of today’s fast-paced production environments. To discuss your specific requirements, application, and industry, contact us today to learn more about our flexible adhesive products.

Leave a comment

All comments are moderated before being published.

Situs ini dilindungi oleh reCAPTCHA dan berlaku Kebijakan Privasi dan Persyaratan Layanan Google.